Is your warehouse floor overflowing, or is your retail stockroom a chaotic mess? Struggling with inefficient storage slows operations, damages goods, and even creates safety risks. As specialist Industrial Storage Shelving Manufacturers, we see these challenges daily and provide robust, reliable industrial shelving solutions to bring order and efficiency back.

Choosing the right heavy-duty industrial storage rack involves matching the shelving system to your specific needs. Key factors include calculating required load-bearing capacity, selecting the appropriate shelf material (typically heavy-duty steel), determining the best shelf type (like pallet rack, wire shelving, or cantilever), ensuring adjustability, and confirming dimensions (assembled height, width, depth). Proper selection ensures optimal space utilization, safety, and durability for warehouse, industrial, or even garage storage applications.

What Defines Heavy-Duty Industrial Shelving and Why is it Essential?

When we talk about industrial shelving, we’re referring to storage systems specifically engineered to handle the demanding environments and substantial loads found in commercial and industrial settings. Unlike standard consumer shelving, heavy-duty industrial shelving is built for strength and durability, designed to safely store bulk goods, heavy equipment, pallet loads, or large quantities of inventory. Think warehouse shelving, factory storage, retail backrooms, automotive workshops, and even robust garage storage for homeowners needing serious capacity.

As manufacturers, we define “heavy-duty” through specific design and material choices. This typically involves using high-gauge steel for components like the upright frames and beams, employing robust construction techniques, and ensuring high load-bearing capacity per shelf level and for the overall shelving unit. The goal is to provide a reliable, long-lasting storage shelf solution that maximizes vertical storage safely and efficiently. It’s not just about holding things; it’s about optimizing workflow, protecting assets, and ensuring workplace safety – critical factors for warehousing and logistics companies, industrial manufacturers, and construction companies managing building materials.

Investing in the right industrial storage rack system is essential for operational efficiency. Proper storage shelving allows businesses to:

-

Maximize Space: Utilize vertical height effectively, freeing up valuable floor space.

-

Improve Organization: Keep inventory, tools, or materials clearly arranged and accessible.

-

Enhance Safety: Reduce risks associated with improperly stacked items or overloaded, inadequate shelving.

-

Increase Productivity: Faster locating and retrieval of items saves time and labor costs.

-

Protect Inventory: Minimize damage to stored goods.

For retailers, this means better stock management and potentially higher inventory levels on hand. For logistics firms, it translates to faster throughput. For manufacturers, it means organized components and safer workshops.

Calculating Your Needs: How Much Load Capacity Do You Require?

One of the most critical factors in selecting industrial shelving is determining the required load-bearing capacity. Overloading a shelving unit is a serious safety hazard and can lead to structural failure, damaged goods, and potential injuries. Underestimating your needs means you might buy a system that isn’t robust enough, while overestimating can lead to unnecessary expense. As manufacturers, we strongly advise carefully assessing your storage requirements before making a purchase.

Start by identifying the heaviest items you intend to store on a single shelf. Consider not just individual item weight but the total weight when the shelf is fully loaded. For example, if you’re storing boxes, calculate the weight per box and multiply by the maximum number of boxes that will fit on one shelf. If dealing with pallet loads for a pallet rack system, you need the maximum weight of a fully loaded pallet. Always factor in a safety margin – don’t plan to load shelves to their absolute maximum stated capacity routinely. Check the manufacturer’s loading recommendations carefully; capacity is often specified per shelf level, assuming evenly distributed weight.

Consider the type of load as well. A uniformly distributed load (like boxes of the same size) stresses the shelf differently than point loads (like heavy machinery parts) or oddly shaped items. Our heavy-duty shelving options, like the popular 4-tier industrial duty steel freestanding units or larger 5-tier and 6-tier systems, come with clear weight ratings. It’s crucial to match these ratings to your heaviest anticipated load. For particularly heavy loads or specialized items (like lumber or pipes), specific shelf type solutions like cantilever racking might be necessary. Remember, safety is paramount. If unsure, it’s always better to opt for a higher capacity rating. Consult our load capacity guide for detailed advice.

Exploring the Options: What Are the Key Types of Industrial Storage Racks?

Industrial shelving systems come in a variety of configurations, each designed for specific storage needs and environments. Understanding the main types helps you choose the most efficient solution for your application, whether it’s organizing a warehouse, streamlining retail backstock, or setting up efficient garage storage. As manufacturers, we produce a wide range of industrial options:

-

Pallet Rack Systems: The workhorse of most large warehouses and distribution centers. Designed specifically to store palletized goods using forklifts. Key components include upright frames and horizontal load beams. Different styles exist (selective, drive-in, push-back) offering varying density and accessibility. Our heavy-duty pallet rack systems are engineered for high capacity and durability.

-

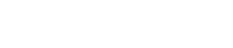

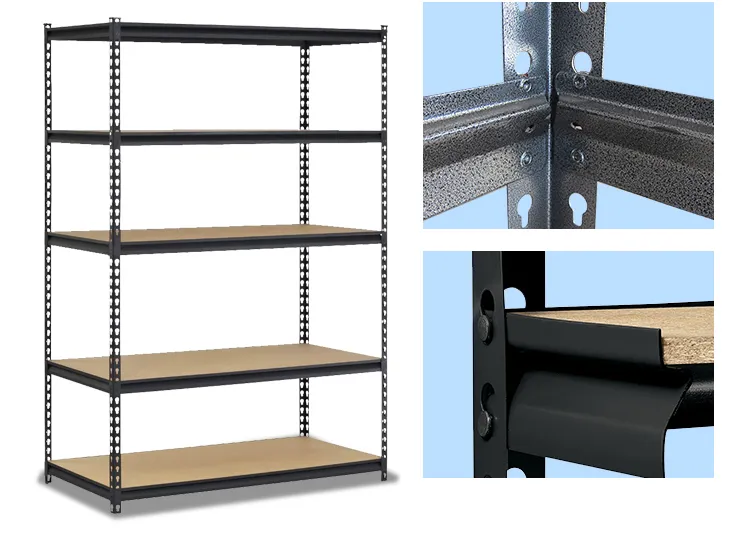

Boltless Shelving (Rivet Shelving): Highly popular for its easy assembly and adjustability. Uses rivets that slot into keyholes on the upright posts, requiring no nuts or bolts. Ideal for storing boxes, bins, tools, and general inventory in warehouses, workshops, retail stockrooms, and garages. Often available as multi-purpose 3-tier, 4-tier industrial, or 5-tier units.

-

Wire Shelving: Features open wire construction, which improves air circulation, reduces dust accumulation, and increases visibility. Often used in food service, healthcare, electronics storage, and retail display due to its clean look and ease of cleaning. Heavy duty steel wire shelving offers substantial capacity for various applications. Available in chrome, black (storage shelving unit in black), or other finishes.

-

Steel Shelving (Solid Shelving): Traditional metal shelving with solid steel shelves. Provides a stable, flat surface suitable for storing smaller items, parts, files, or items that might fall through wire shelves. Often found in offices, workshops, and industrial settings. Can be open (braced) or closed (with back and side panels).

-

Cantilever Racking: Designed specifically for storing long, bulky, or irregularly shaped items like lumber, pipes (industrial pipe), steel bars, or furniture. Consists of vertical columns (upright bases) with horizontal arms extending outwards, providing unobstructed horizontal storage space.

Choosing the right shelf type depends entirely on what you need to store, how it’s handled (by hand, forklift), and the environment. Sometimes, a combination of different shelving products is the best solution. Explore our full range of industrial shelving types to see what fits best.

Why is Steel the Gold Standard for Shelf Material in Industrial Settings?

When it comes to heavy-duty industrial shelving, steel is overwhelmingly the preferred shelf material, and for very good reasons. As manufacturers committed to producing durable and reliable storage systems, we primarily utilize high-quality steel in our shelving unit construction due to its exceptional strength and durability.

Steel offers an excellent strength-to-weight ratio, meaning it can support significant heavy loads without excessive bulk or weight in the rack itself. This is crucial for maximizing storage capacity safely. Steel is resistant to impact, wear, and tear common in busy industrial environments like warehouses, manufacturing plants, or automotive repair shops. Properly finished steel shelves (e.g., powder-coated) also offer good resistance to corrosion, moisture, and temperature fluctuations, ensuring a long service life even in less-than-ideal conditions. You’ll often see specifications like “heavy duty steel wire” or “heavy duty steel freestanding garage storage shelving unit” emphasizing this core material.

Compared to alternatives like wood or plastic, steel provides superior load-bearing capacity and fire resistance. While wood might be used for lighter duties, it can warp, splinter, or absorb moisture, and it’s combustible. Plastic shelving typically has much lower weight limits and may become brittle over time or deform under load. For the demanding requirements of industrial storage, where safety and longevity are paramount, steel shelves provide the necessary structural integrity and peace of mind. The inherent strength of steel allows for designs like robust pallet rack systems and high-capacity warehouse shelving that simply wouldn’t be feasible with other materials.

Boltless vs. Bolted: Which Shelving Unit Offers Easier Assembly and Adjustability?

A common decision point when selecting industrial shelving, particularly for general-purpose storage (not necessarily heavy pallet loads), is choosing between boltless and traditional bolted designs. Both have their merits, but boltless shelving has gained significant popularity, especially for applications requiring flexibility and straightforward setup.

Boltless Shelving (Rivet Shelving):

-

Pros:

-

Easy Assembly: This is the primary advantage. Components typically snap or slot together using rivets and keyholes, often requiring only a rubber mallet. This drastically reduces installation time and labor costs. No fumbling with nuts, bolts, or wrenches. Look for terms like “easy assembly.”

-

Adjustability: Adjusting shelf heights is usually very simple – just tap the beams or shelf supports out and relocate them to different slots on the upright posts. This makes it easy to reconfigure the shelving unit as storage needs change.

-

Cost-Effective: Often more affordable initially due to simpler manufacturing and faster assembly.

-

-

Cons:

-

May have slightly lower maximum capacities compared to some heavy-duty bolted systems, although high-capacity boltless shelving options are widely available.

-

Connections might feel slightly less rigid than a fully bolted frame to some users, though properly designed systems are very stable.

-

Bolted Shelving:

-

Pros:

-

Potentially higher rigidity and maximum load capacities in some very heavy-duty configurations.

-

Connections are very secure once tightened.

-

-

Cons:

-

Assembly required is significantly more time-consuming and complex, needing tools (wrenches) and potentially two people.

-

Adjusting shelf heights requires unbolting and re-bolting beams, making reconfiguration more laborious.

-

For most general warehouse, garage storage, retail, or workshop applications where heavy-duty capacity is needed but extreme loads aren’t the norm, boltless shelving offers an excellent combination of strength, easy assembly, and adjustability. As manufacturers, we offer robust boltless designs that meet stringent commercial grade standards, providing a reliable and user-friendly storage shelving solution. Compare assembly methods on our boltless vs. bolted shelving page.

Maximizing Vertical Space: How Uprights and Number of Shelves Impact Storage?

Effectively utilizing vertical storage is key to optimizing any storage space, whether it’s a vast warehouse or a compact garage. The design of the industrial shelving system’s upright frames and the chosen number of shelves directly influence how much you can store vertically and how efficiently you can access it.

The assembled height of the upright frames determines the maximum vertical storage potential of your shelving unit. Taller uprights allow for more shelf levels, significantly increasing storage density without consuming additional floor space. When choosing upright height, consider your ceiling height, the reach height for manual picking (or the lift height of handling equipment like forklifts for pallet rack systems), and local fire code regulations regarding flue space between inventory and sprinkler systems. As manufacturers, we offer uprights in various standard heights and can often provide custom heights for large projects.

The number of shelves you incorporate within those uprights dictates the granularity of your storage. More shelves mean smaller vertical spaces between them, suitable for shorter items or maximizing the count of smaller boxes. Fewer shelves create larger openings, ideal for taller items. The beauty of adjustable shelves, common in boltless shelving and many metal shelving systems, is the ability to customize these vertical spaces. You can start with a standard 3-tier, 4-tier industrial, 5-tier, or 6-tier configuration and easily add or remove shelves or change their spacing later as your inventory profile evolves. This flexibility is crucial for adapting your storage systems over time.

Dimension Details: Getting the Assembled Width and Depth Right?

While maximizing height is important, choosing the correct assembled width and assembled depth for your industrial shelving is equally crucial for efficient space utilization and practical usability. These dimensions determine how much horizontal space each shelf industrial unit occupies and how well items fit onto the shelves.

Assembled Width: This refers to the horizontal distance from the outside of one upright frame to the outside of the other. Wider shelves accommodate larger items or allow more smaller items to be stored side-by-side. When planning rows of shelving, consider the total width of multiple units plus the necessary aisle width for access (walking, carts, or forklifts). Standard widths often range from 36 inches to 96 inches or more, particularly for pallet rack beams.

Assembled Depth: This is the distance from the front edge of the shelf to the back edge. The required depth depends entirely on the size of the items being stored. Standard depths might range from 12 inches up to 48 inches or more.

-

Deeper shelves (e.g., 24″, 36″, 48″) are suitable for larger boxes, equipment, or pallet storage (common pallet sizes influence pallet rack depths).

-

Shallower shelves (e.g., 12″, 18″) work well for smaller bins, tools, files, or items in retail displays where easy access to everything is needed. Storing items deeper than the shelf can create overhangs and instability. Conversely, shelves that are too deep for the items being stored can lead to wasted space at the back or items getting “lost.”

As manufacturers, we offer a wide array of standard width and depth combinations for our shelving products. Carefully measure your available space and the dimensions of your typical inventory before ordering. Consider how items will be placed and retrieved. For instance, a very deep shelving unit accessed only by hand might make reaching items at the back difficult. Accurate dimensioning ensures your industrial storage rack fits the space and the function perfectly. Need help planning? Use our online space planning tool (if available).

Freestanding vs. Fixed: What Works Best for Your Warehouse or Garage Storage?

Most industrial shelving systems are designed as freestanding units, meaning they stand independently without needing to be bolted to walls or floors (though anchoring is often recommended or required for safety, especially for tall units or in seismic zones). This freestanding nature offers significant advantages in terms of flexibility.

Freestanding Shelving:

-

Flexibility: Easy to reposition, reconfigure, or relocate units as your needs change or if you move facilities. This is ideal for growing businesses, dynamic warehouse environments, or even setting up temporary storage for home depot events or construction projects.

-

No Structural Modification: Doesn’t require drilling into walls or floors (unless anchoring for safety).

-

Versatility: Can be placed back-to-back to create aisles or positioned along walls. Units like “industrial duty steel freestanding garage storage shelving unit” are specifically marketed for this ease of placement.

Fixed/Anchored Shelving:

-

Enhanced Stability: Bolting units to the floor and/or wall significantly increases stability and safety, crucial for very tall racks, heavy loads, or areas prone to vibrations or seismic activity. Often a requirement by safety codes (e.g., OSHA in the US).

-

Permanent Installation: Provides maximum security against tipping or movement.

2 Pack Wall Mounted Shelving 1.5x4ft Garage Storage Rack

For most applications, the inherent stability of well-designed heavy-duty freestanding industrial shelving is sufficient, especially for units of moderate height. However, safety must always be the priority. As manufacturers, we strongly recommend consulting local building codes and safety regulations regarding anchoring requirements for your specific installation, height, and load. Always follow manufacturer guidelines for assembly required and anchoring. For tall pallet rack systems in a busy warehouse, anchoring is almost always essential. For typical garage storage, freestanding might be adequate, but anchoring adds an extra layer of safety.

Partnering with a Manufacturer: What Ensures Durability and Design Efficiency?

Choosing the right industrial shelving involves more than just picking dimensions and capacities; it’s about selecting a reliable manufacturing partner who prioritizes quality, safety, and intelligent design. As direct Industrial Storage Shelving Manufacturers, we control the entire process, from raw material selection to final quality checks, ensuring our shelving products meet the high standards our diverse customers expect – from demanding warehouse environments to quality-conscious home users seeking robust garage storage.

Durability starts with materials and construction. We utilize high-grade steel, employ precise manufacturing techniques (like robotic welding for consistency), and apply durable finishes (like powder coating in various shelf color family options) to resist wear, tear, and corrosion. Our rigorous quality control checks at multiple stages ensure that every shelving unit, whether it’s a heavy-duty pallet rack or a commercial grade wire shelving unit, offers long-lasting performance.

Design Efficiency goes beyond just strength. It encompasses:

-

Space Utilization: Designing upright profiles and beam connections to maximize usable storage space.

-

Adjustability: Creating systems like boltless shelving with easily adjustable shelves for maximum flexibility.

-

Ease of Assembly: Engineering components for straightforward, quick setup (easy assembly).

-

Safety Features: Incorporating safety locks on beams, providing clear loading recommendations, and designing for stability.

-

Customization: Offering a variety of configurations, sizes, and accessories (drawer units, specialized racks like garment rack options) to tailor solutions.

By partnering directly with a manufacturer like us, you gain access to expertise, potentially better pricing by eliminating intermediaries, and the assurance of consistent quality and support. We understand the needs of logistics companies managing pallet flows, retailers optimizing stockrooms, construction firms storing building materials, and homeowners needing reliable storage shelving. Contact us directly to discuss how our manufacturing capabilities can meet your specific industrial storage requirements.

Frequently Asked Questions (FAQs)

How much weight can typical heavy-duty industrial shelving hold per shelf?

Load capacity varies significantly depending on the shelf type, size (assembled width and depth), shelf material gauge, and beam design. Standard heavy-duty boltless shelving might hold anywhere from 500 lbs to over 2,000 lbs per shelf level (evenly distributed). Pallet rack beams can be rated for 5,000 lbs or much more per pair. Always check the manufacturer’s specific loading recommendations for the exact shelving unit you are considering.

Is assembly difficult for industrial shelving racks?

Boltless shelving systems are designed for easy assembly, often requiring only a rubber mallet. Bolted systems require more time and tools (wrenches). Pallet rack assembly is more involved and often best handled by experienced installers, especially for large or tall systems. Always follow the manufacturer’s instructions carefully.

Can I adjust the shelf height easily after the unit is assembled?

Yes, for most adjustable shelves systems like boltless shelving or wire shelving, adjusting heights is straightforward. Beams or shelf supports can typically be removed and repositioned without fully dismantling the shelving unit. Bolted systems require unbolting and re-bolting, which is more time-consuming.

What type of industrial shelving is best for storing long items like pipes or lumber?

Cantilever racking is specifically designed for long, bulky items. It uses arms extending from central columns, providing unobstructed horizontal storage space, making it much safer and more efficient than trying to store such items on standard pallet rack or metal shelving.

How do I maintain and clean industrial metal shelving?

Generally, steel shelves require minimal maintenance. Regularly inspect for any signs of damage, overloading, or loose connections. Cleaning typically involves dusting or wiping down with a damp cloth. For greasy or grimy environments (like automotive shops), use a mild degreaser. Wire shelving is particularly easy to clean due to its open design. Promptly clean spills to prevent potential corrosion, even with coated finishes.

Are your shelving units suitable for commercial environments like retail stockrooms or hotels?

Absolutely. Our commercial grade industrial shelving, including boltless shelving, wire shelving, and standard metal shelving, is widely used in retail backrooms, hotel storage areas, restaurants, and other commercial settings due to its durability, adjustability, and professional appearance (available in various shelf color family options like black or chrome).

Key Takeaways: Choosing Your Industrial Shelving Solution

-

Prioritize Load Capacity: Always calculate your maximum weight requirements per shelf and choose a shelving system with adequate, clearly stated loading recommendations. Safety first!

-

Select the Right Type: Match the shelf type (pallet rack, boltless, wire shelving, cantilever) to the items you need to store and how they are handled.

-

Steel for Strength: Heavy-duty steel construction ensures the durability and longevity needed for industrial and commercial use.

-

Embrace Adjustability: Adjustable shelves, especially in boltless shelving designs, offer flexibility to adapt your storage as needs change.

-

Optimize Space: Use appropriate assembled height, width, and depth dimensions along with smart vertical storage planning to maximize your area.

-

Consider Assembly: Boltless systems offer easy assembly, saving time and labor, while bolted systems may offer higher capacity in some specific designs.

-

Partner Wisely: Working with a reputable Industrial Storage Shelving Manufacturer ensures quality materials, efficient design, reliable support, and adherence to safety standards.

Ready to transform your cluttered space into an organized, efficient, and safe environment? As experienced manufacturers, we offer a comprehensive range of industrial storage shelving solutions designed for performance and durability.

Contact us today to discuss your specific needs, request a quote, or get expert advice on selecting the perfect industrial storage rack system for your business or home!

Post time: Apr-29-2025