Table of Contents

1. Introduction

The choice between boltless and traditional shelving can greatly impact how well items are organized and accessed. This article will explore the differences between these two options, focusing on their unique benefits and best use cases. We’ll also answer common questions about durability, load capacity, and installation to help you make the best choice for your storage needs. By the end, you’ll have a clear understanding of which shelving option is right for you.

2. Boltless Shelving

2.1 Definition

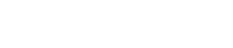

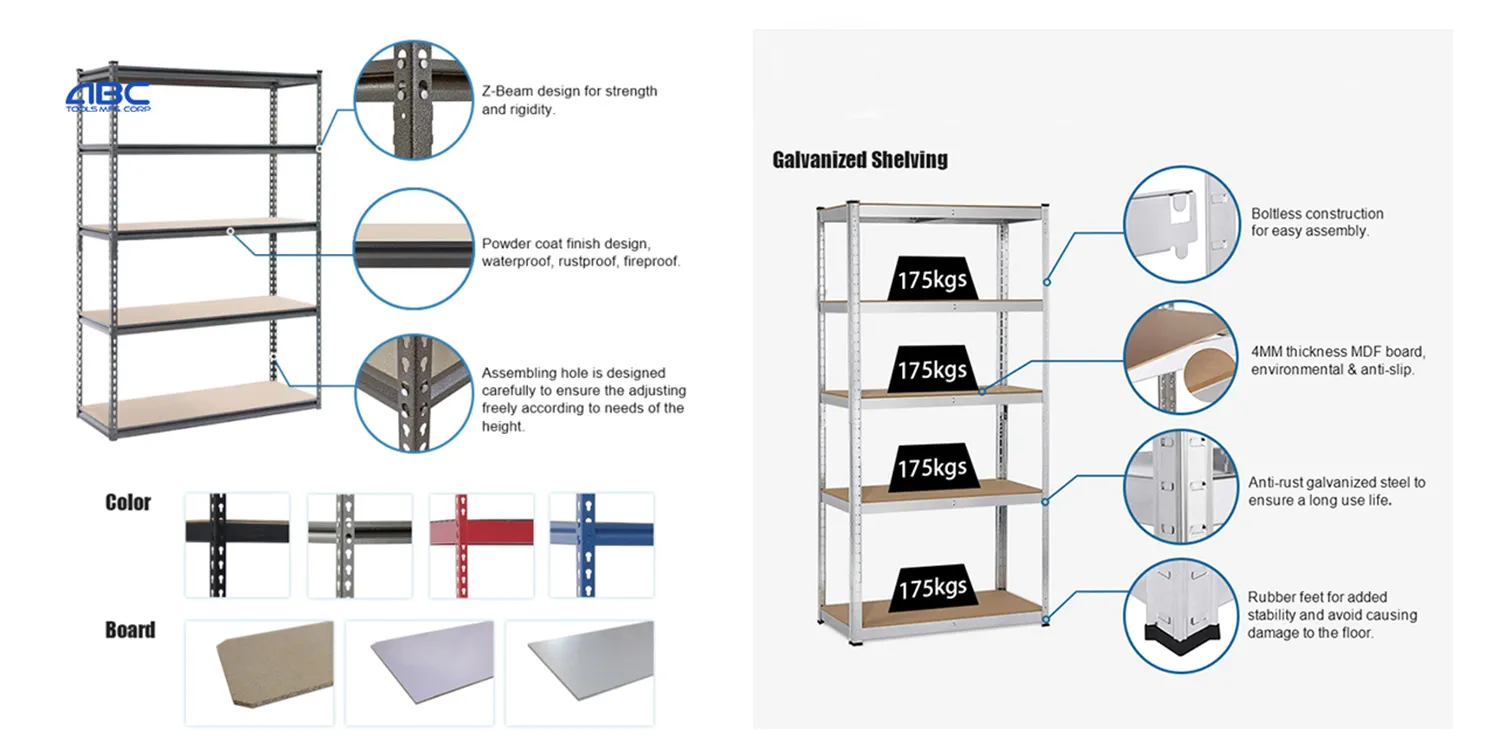

Boltless shelving, also known as clip or rivet shelving, is a storage system that uses an interlocking design for easy assembly without bolts or screws. It’s known for its simplicity, flexibility, and quick installation.

2.2 How It Works

Boltless shelving is easy to assemble with minimal tools. Shelves, usually made of steel or aluminum, have pre-drilled holes that align with slots in the vertical supports. The shelves clip or slot into place, creating a stable structure that can be easily adjusted to fit different storage needs.

2.3 Common Uses

Boltless shelving is versatile and widely used in warehouses, garages, workshops, and retail spaces. It’s ideal for heavy loads and changing storage needs, providing a practical solution for organizing tools, equipment, and products.

2.4 Advantages

The main advantages of boltless shelving are easy assembly and adjustability. It requires no complex tools, making it perfect for quick setups. The flexibility to adjust shelf heights also accommodates different items and changing needs. Additionally, boltless shelving is often more affordable than traditional systems.

2.5 Potential Drawbacks

While boltless shelving is functional, it may lack decorative appeal due to its industrial look. However, a sleek finish or added decor can improve its appearance. It may also be less rigid than traditional shelving, especially with heavy loads or uneven floors.

3. Traditional Shelving

3.1 Definition

Traditional shelving uses bolts, welds, or fixed connections for assembly, requiring more complex installation and specialized tools compared to boltless systems.

3.2 How It Works

Traditional shelving is assembled by aligning vertical posts, attaching shelves with bolts or welds, and securing the structure to the floor or wall. This creates a more rigid and permanent solution, ideal for situations where stability and load capacity are key.

3.3 Common Uses

Traditional shelving is often used in libraries, offices, and homes. Libraries rely on it for its durability to hold heavy books, while offices use it for a clean, professional look. In homes, especially in garages and basements, it’s preferred for handling heavier loads and providing a long-term storage solution.

3.4 Advantages

The main advantage of traditional shelving is its strength. Bolted or welded connections ensure a stable structure that can safely support heavy items. It also offers a variety of customization options in materials, finishes, and designs, making it a popular choice for spaces where appearance matters, like retail stores and showrooms.

3.5 Potential Drawbacks

Traditional shelving’s main drawbacks are its complexity and inflexibility. Assembly is more time-consuming, often requiring specialized tools and skills, leading to higher costs. Adjustments are difficult, as they may require disassembling parts or drilling new holes, which is less convenient when storage needs change frequently.

4. Key Differences Between Boltless and Traditional Shelving

4.1 Assembly Process

Boltless shelving is designed for easy, tool-free assembly, often needing just a rubber mallet. Components snap together quickly, making it simple for anyone to set up. Traditional shelving, on the other hand, involves aligning posts, attaching shelves with bolts or welds, and securing the structure, which is more complex and time-consuming, requiring specialized tools and skills.

4.2 Flexibility & Adjustability

Boltless shelving is highly flexible and adjustable. Its modular design allows easy customization of shelf heights and configurations to meet changing storage needs. Shelves can be repositioned with minimal effort. Traditional shelving, though sturdy, is less adaptable and requires disassembly or drilling for adjustments.

4.3 Strength & Durability

Both types are durable, but traditional shelving generally offers greater structural integrity due to bolted or welded connections, making it ideal for extremely heavy loads. Boltless shelving is still strong, with many units supporting up to 800 pounds per shelf.

4.4 Cost Efficiency

Boltless shelving is typically more cost-effective. Its simple assembly reduces installation costs, and the modular design means you only buy what you need. Traditional shelving may have higher upfront costs, but its durability can justify the investment for heavy-duty storage needs.

4.5 Aesthetics

Aesthetics are subjective, but traditional shelving often provides a more polished, professional look. Boltless shelving has an industrial feel, though sleeker finishes are available. Traditional shelving also offers more customization in materials and design.

4.6 Maintenance

Boltless shelving is easier to maintain, with its open design allowing quick inspections and adjustments without disassembly. Traditional shelving may require more effort for inspections and repairs.

Boltless shelving excels in ease of assembly, flexibility, and cost-effectiveness, while traditional shelving offers superior strength, customization, and a refined appearance. The ideal choice varies based on your unique requirements, budget, and personal preferences.

5. FAQs

1) Q: Which is easier to assemble: boltless or traditional shelving?

A: Boltless shelving is much easier to assemble. It usually requires just a rubber mallet, while traditional shelving involves bolts and specialized tools, making it more complex and time-consuming.

2) Q: Can boltless shelving handle heavy loads like traditional shelving?

A: Yes, boltless shelving can handle heavy loads, with standard units supporting up to 800 pounds per shelf. Traditional shelving might have a higher load capacity depending on its construction, making it ideal for extremely heavy items.

3) Q: What are the costs associated with each type?

A: Boltless shelving is generally more affordable, both in purchase price and installation costs. Traditional shelving tends to be more expensive due to its complex assembly and higher material costs.

4) Q: Which shelving option is more versatile?

A: Boltless shelving is more versatile due to its customizable design, allowing for easy adjustments in shelf height and configuration to fit different storage needs.

5) Q: Is boltless shelving sturdy enough for industrial use?

A: Yes, boltless shelving is sturdy enough for industrial use, especially when made from high-quality steel. It’s designed to handle heavy loads in demanding environments.

6) Q: Can traditional shelving be adjusted as needs change?

A: Traditional shelving can be adjusted, but it’s less flexible. Adjustments usually require disassembly or drilling, making it more cumbersome compared to boltless shelving.

7) Q: Which option is better for small spaces?

A: Boltless shelving is better for small spaces due to its modular design, which allows for efficient use of space and various layout configurations.

8) Q: Is one type of shelving more durable than the other?

A: Both types can be durable, but traditional shelving often has an edge in structural integrity due to bolted or welded connections. Boltless shelving is also durable, especially with high-quality materials.

9) Q: Which shelving is more aesthetically pleasing?

A: Aesthetic appeal is subjective. Traditional shelving often has a more classic look, while boltless shelving has an industrial style. Your decision should be guided by your individual needs and preferences.

10) Q: Which shelving is better for business vs. personal use?

A: For businesses, boltless shelving is often preferred for its easy assembly, cost-effectiveness, and adaptability. Traditional shelving suits environments needing heavy-duty storage and a polished appearance. For personal use, the choice depends on what you’re storing and the look you want.

11) Q: How long does each type of shelving last?

A: Both can last for years with proper care. Traditional shelving may last longer due to its robust construction, but high-quality boltless shelving is also very durable.

6. Choosing the Right Shelving for Your Needs

6.1 Key Considerations

6.1.1 Space Constraints

– Boltless Shelving: Flexible and easy to reconfigure for different spaces.

– Traditional Shelving: Ideal for permanent installations with a fixed layout.

6.1.2 Weight Capacity

– Traditional Shelving: Offers higher weight limits due to bolted or welded construction.

– Boltless Shelving: Strong, supporting up to 800 pounds per shelf, with heavy-duty options available.

6.1.3 Budget

– Boltless Shelving: Generally more affordable, with lower installation costs.

– Traditional Shelving: Higher upfront costs, but long-term durability.

6.1.4 Flexibility & Adjustability

– Boltless Shelving: Highly adaptable with easy adjustments.

– Traditional Shelving: Less flexible, requiring disassembly or modifications for adjustments.

6.1.5 Aesthetics

– Traditional Shelving: Provides a polished, professional look.

– Boltless Shelving: Has an industrial feel, though modern finishes are available.

6.1.6 Ease of Assembly

– Boltless Shelving: Quick, tool-free setup.

– Traditional Shelving: More complex, requiring specialized tools.

6.1.7 Durability

– Both: Durable when made with quality materials.

– Traditional Shelving: Bolted or welded connections provide added structural integrity.

6.1.8 Maintenance

– Boltless Shelving: Easier to maintain with open designs for quick inspections.

– Traditional Shelving: May require more effort for repairs or modifications.

6.2 Scenarios

6.2.1 Warehouses and Distribution Centers:

– Boltless Shelving: Favored for flexibility and cost-effectiveness.

– Traditional Shelving: Chosen for heavy loads and permanent setups.

6.2.2 Retail Stores and Showrooms:

– Traditional Shelving: Preferred for a polished, product-focused display.

– Boltless Shelving: Works for modern, minimalist aesthetics.

6.2.3 Garages and Workshops:

– Boltless Shelving: Great for adaptable, heavy-duty storage.

– Traditional Shelving: Ideal for a professional, organized appearance.

6.2.4 Home Storage:

– Boltless Shelving: Cost-effective, flexible, and easy to assemble.

– Traditional Shelving: Best for custom, permanent installations like built-in bookcases.

Your choice between boltless and traditional shelving should reflect your storage needs, budget, and style preferences. By evaluating these factors, you can select the shelving that best enhances your space’s efficiency, organization, and look.

7. Conclusion

For spaces that need adaptability and cost-effectiveness, boltless shelving is ideal, especially in warehouses, garages, and retail settings. If you require a sturdy solution for heavy loads or a refined aesthetic, traditional shelving is a better fit, particularly in libraries, offices, and high-end retail environments.

Post time: Aug-23-2024